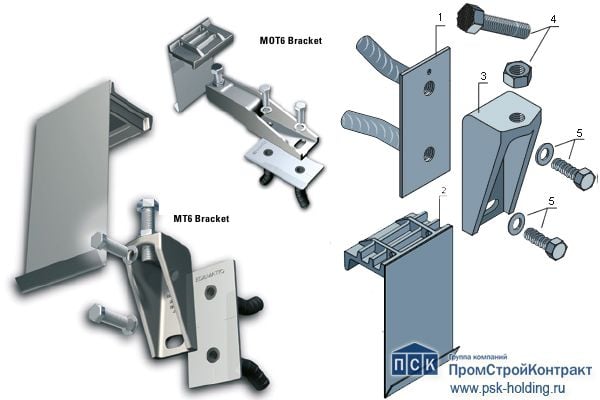

Система узлов для навесных сборных конструкций MT BRACKET Edilmatic

The MT Bracket system is proposed as a simple and effective solution to support prefabricated panels externally mounted on beams and / or pillars. Wide adjustment and easy positioning of the inserts are the strengths of the MT Bracket, available in 5 different models depending on the loading needed (from 2t 12t)

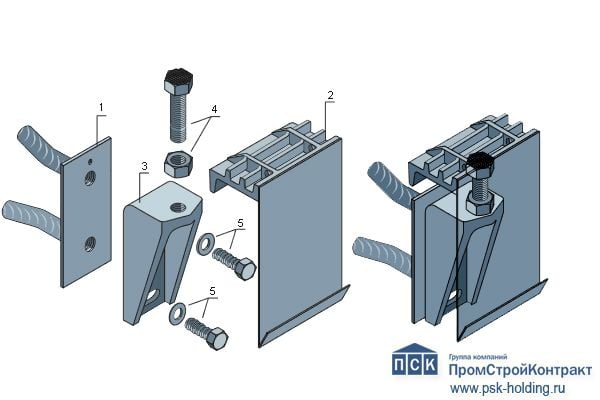

The system consists of three elements:

• CLAMPED PLATE (INSERT) to be positioned on the load-bearing element (COLUMN)

• LOAD DISTRIBUTOR (INSERT) to be positioned on the load element (PANEL)

• BRACKET connecting the two elements.It is supplied with nut and bolt and locking bolts and washers

Depending on the capacity required, three models are available:

MT4 bracket

maximum capacity 40 kN

(safety factor > 3)

MT6 bracket

maximum capacity 60 kN

(safety factor > 3)

MT9 bracket

maximum capacity 90 kN

(safety factor > 3)

MT12 bracket

maximum capacity 120 kN

(safety factor > 3)

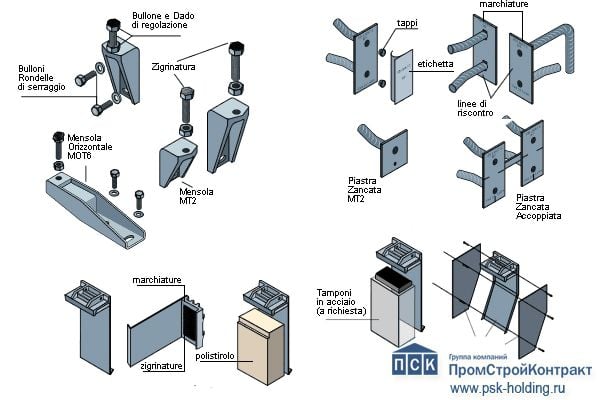

CLAMPED PLATE

Insert to be positioned in the LOAD-BEARING element, with no additional reinforcement in the positioning area; it consists of a specially dimensioned galvanised plate (the dimensions of the latter depend upon the Bracket type) two threaded increased-bond rebars having a variable diameter (depending on the relevant capacity) are positioned on both sides there are “striker lines” being exactly positioned on the median parts of the plate, in order to simplify a positioning of the latter while arranging the casting of the structures.

During the finishing phase, PVC plugs are inserted in the holes being in the front part of the insert, then, a sticker reporting the data of the clamped plate is applied, in order not to allow the "grout" to be reached.

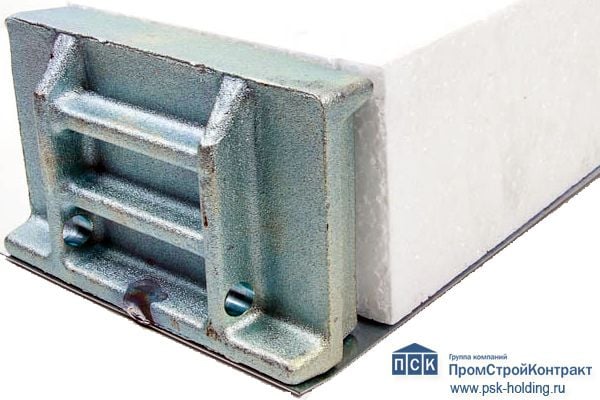

LOAD DISTRIBUTOR

Insert to be positioned in the load element, which consists of a central "body" equipped with a rear shaped closing sheet; it is supplied with polystyrene applied during the finishing phase to create a bearing space for the Bracket.

The load distributor is equipped with longitudinal stiffening ribs to allow an optimal load distribution to be achieved while positioning the Bracket on the Bolt as well as with lower lateral reinforcements to avoid the Adjustment Bolt to come out, while moving laterally. The bearing surface is knurled to hinder a slipping of the element, once the assembling phase is finished.

The load distributors can be supplied in a different width depending upon the concerned scope.

MT WALL BRACKET

UNION element between the two components, which acts as bearing part for the load element.

Both the Nut and the Adjustment Bolt are integral parts of the Bracket, they are also needed to carry out vertical adjustments of the element: the Bolt has a knurled head (cross knurling) to avoid a slippage while positioning.

In the middle of the bracket there is an identification marking which reports the maximum applicable capacity:

for example: EDILMATIC MT6 = max capacity 6 tons (60 kN)

The maximum Capacity reported in the Table is the Characteristic Operational Resistance of the System. This value has been calculated by carrying out laboratory tests, i.e. by submitting the system to Ultimate Tensile Stress Tests as well as applying a safety factor equal to >3, to the measured value.

All our brackets are equipped with BOLT and ADJUSTMENT NUT (already screwed in/on) as well as with BOLTS and TIGHTENING WASHERS, unless the customer has different needs/submits special requests.

Our Special Depressed and Raised Brackets are equipped with adjustment and tightening bolts

Testing certificates regarding the raw materials we utilize and internal control certificates can be supplied by customers' request.

| Показатель | Значение |

|---|

Отличительные особенности

- экономичность использования;

- простота монтажа системы и ее использования;

- уменьшение металлоемкости железобетонных конструкций;

- удобство складирования и хранения железобетонных изделий.

СПЕЦУСЛОВИЯ